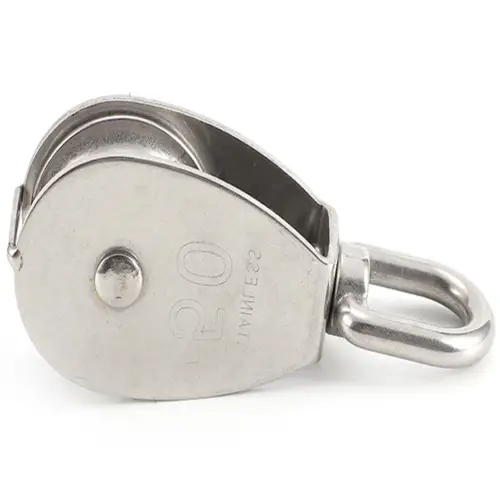

Stainless Steel Swivel Sheave Pulley for Industrial Use

Our Stainless Steel Swivel Sheave Pulley is an essential component of any lifting system. Made of high-quality stainless steel 304/316/316L, it offers excellent corrosion resistance, durability, and load-bearing capacity. The pulley has a bright and smooth surface, ensuring smooth operation and reducing friction. It is available in various sizes ranging from M15 to M50, making it suitable for a wide range of applications.

Product Description

The Stainless Steel Swivel Sheave Pulley is a single-wheel lifting pulley square type for lifting. It comes in different sizes, including M15, M20, M25, M32, M50, M75, and M100, with detailed sizes provided in a table format below. The pulley can be made of stainless steel 304, stainless steel 316, stainless steel 316L, or other special materials. It has a monthly capacity of 500 tons per month, and the price terms are FOB ZheJiang or EXW.

Key Features:

- High-quality stainless steel material

- Corrosion-resistant

- Durable and strong load-bearing capacity

- Bright and smooth surface

- Available in various sizes

- Monthly capacity of 500 tons per month

- Competitive pricing

Details of the figure

| Size | A | B | C | D | E |

| mm | mm | mm | mm | mm | |

| M75 | 23 | 33 | 155 | 75 | 15 |

| M100 | 25 | 40 | 191 | 100 | 17 |

Detailed Photos

[Insert relevant photos of product]

FAQs

Q1: What is the Stainless Steel Swivel Sheave Pulley made of?

A1: The pulley is made of high-quality stainless steel, such as stainless steel 304, stainless steel 316, stainless steel 316L, or other special materials.

Q2: What is the monthly capacity of the Stainless Steel Swivel Sheave Pulley?

A2: The monthly capacity of the pulley is 500 tons per month.

Q3: What is the pricing term for the Stainless Steel Swivel Sheave Pulley?

A3: The price terms are FOB ZheJiang or EXW.

Q4: What sizes are available for the Stainless Steel Swivel Sheave Pulley?

A4: The pulley comes in various sizes, including M15, M20, M25, M32, M50, M75, and M100. Detailed sizes are provided in the table format above.

Q5: Does the Stainless Steel Swivel Sheave Pulley have a bright and smooth surface?

A5: Yes, the pulley has a bright and smooth surface, ensuring smooth operation and reducing friction.

Our company specializes in providing a wide range of high-quality products for industrial use. Some of our other products include agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, Roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing our customers with high-quality products, competitive pricing, and considerate services. We welcome custom drawings and samples and strive to meet and exceed our customers’ expectations.

All the content of this page is from the Internet and is only intended as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Sheave Pulley

Sheave pulleys have several performance characteristics that make them highly efficient and reliable. Firstly, their smooth and precise rotation ensures minimal friction, resulting in improved energy efficiency. Secondly, the sheaves are designed to distribute the load evenly, preventing unnecessary stress on the system. Additionally, sheave pulleys are known for their durability and resistance to wear and tear, allowing them to withstand heavy usage without compromising performance.

Types and Characteristics of Sheave Pulley

There are various types of sheave pulleys available, each with its own unique characteristics. One common type is the fixed sheave pulley, which provides a stable and consistent rotation. Another type is the adjustable sheave pulley, allowing for flexibility in adjusting the speed and tension of the system. Additionally, there are also multi-groove sheave pulleys that can accommodate multiple belts, increasing the load capacity.

Advantages of Sheave Pulley made of Different Materials

The material used in the construction of a sheave pulley greatly influences its performance and durability. Sheave pulleys made of stainless steel offer excellent corrosion resistance, making them suitable for marine applications. Pulleys made of aluminum are lightweight yet strong, making them ideal for applications that require weight reduction. Furthermore, sheave pulleys made of nylon are known for their low friction coefficient, reducing wear and prolonging the lifespan of the system.

Application of Sheave Pulley in Various Fields

Sheave pulleys find applications in a wide range of industries, showcasing their versatility and importance. In the construction industry, sheave pulleys are used in lifting and hoisting operations, providing the necessary mechanical advantage. In elevators, sheave pulleys play a crucial role in the smooth and efficient movement of the elevator car. Industrial machinery relies on sheave pulleys for power transmission and speed control. Stage equipment, such as theater rigging systems, utilize sheave pulleys for smooth and precise movements. Lastly, in marine applications, sheave pulleys are essential for various operations on ships and boats.

Future Development Trends and Opportunities

The future of sheave pulley products is promising, with several development trends and opportunities on the horizon. As technology advances, the demand for more efficient and compact sheave pulleys is expected to rise. Additionally, the increasing focus on sustainability and energy efficiency presents an opportunity for the development of eco-friendly sheave pulleys. Furthermore, the growing construction and industrial sectors in emerging markets offer potential growth opportunities for the sheave pulley industry.

Choosing a Suitable Sheave Pulley

Selecting the right sheave pulley requires careful consideration of various factors. The load capacity is an important consideration, as it determines the maximum weight the pulley can handle. The material of the pulley should be chosen based on the specific application requirements, considering factors such as corrosion resistance and weight. The diameter and size of the sheave pulley should be compatible with the system it is intended for. Additionally, the type of pulley, whether fixed or adjustable, should be chosen based on the desired functionality. Lastly, the bore size of the pulley should match the shaft it will be mounted on to ensure proper alignment and efficient operation.

In summary, sheave pulleys offer excellent performance characteristics and are available in various types and materials. Their applications in construction, elevators, industrial machinery, stage equipment, and marine applications highlight their importance in multiple industries. The future of sheave pulley products looks promising, with opportunities for innovation and growth. When choosing a sheave pulley, factors such as load capacity, material, diameter and size, type of pulley, and bore size should be carefully considered to ensure optimal performance.