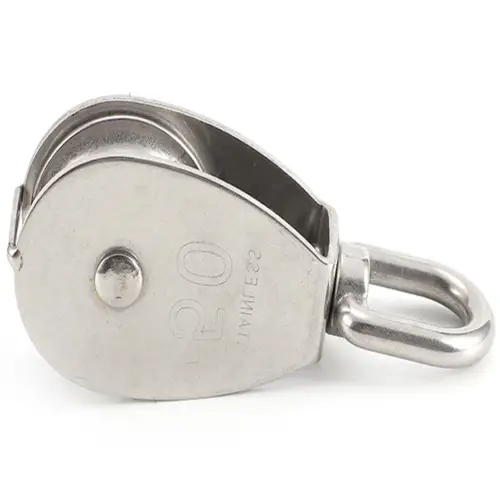

Custom Marine Hardware Stainless Steel Pulley Swivel Pulley Sheave Rope Pulley Air Compressor for Sale

Our stainless steel pulley is a top-of-the-line product. It comes in various sizes ranging from 15mm to 100mm, and can even be customized to meet your needs. Made from high-quality AISI stainless steel 304 or 316, it is durable and can withstand heavy loads. We offer free samples when you send us an inquiry.

Product Specifications

Our Swivel Pulley is the perfect product for your heavy-duty lifting needs. Here are some of its specifications:

| Type | Swivel Pulley |

| Brand | Customizable |

| Size | 15-100MM (Customizable) |

| Standard | AISI |

| Material | Stainless Steel 304 / 316 |

| Sample | Free Sample Available |

| Customization | OEM, ODM, and Ready to Ship |

| Technical Support | 18 Years of Experience and 5 Technical Engineers with More than 10 Years of Experience |

Detailed Photos

Here are some detailed photos of our product:

Certifications

Our product has been tested and certified by various agencies. Here are some of our certifications:

Packaging & Shipping

We take great care in packaging our products to ensure they arrive at their destination in perfect condition. Our products are shipped worldwide and can be delivered within 10-15 days after the order is placed. Faster delivery options are available upon request.

Frequently Asked Questions

Can this pulley withstand heavy loads?

Yes, our stainless steel pulley is capable of handling heavy loads thanks to its high-quality AISI stainless steel 304 or 316 construction.

Is customization available?

Yes, we offer customization services for our pulleys. Simply send us your drawings or samples, and we will work with you to create a product that meets your needs.

How do I place an order?

You can place an order by contacting us through our website or by phone. We accept payment by T/T, with a 30% deposit required for production and the balance due before shipment.

What is the delivery time?

Delivery time is typically between 10-15 days after the order is placed. Faster delivery options are available upon request.

Do you offer other products for industrial use?

Yes, we offer a wide range of products for industrial use, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, planetary gearboxes, timing pulleys, bushings, and more. We also offer customization services for all of our products.

All the content of this page is from the Internet and is only intended as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Sheave Pulley

Sheave pulleys have several performance characteristics that make them highly efficient and reliable. Firstly, their smooth and precise rotation ensures minimal friction, resulting in improved energy efficiency. Secondly, the sheaves are designed to distribute the load evenly, preventing unnecessary stress on the system. Additionally, sheave pulleys are known for their durability and resistance to wear and tear, allowing them to withstand heavy usage without compromising performance.

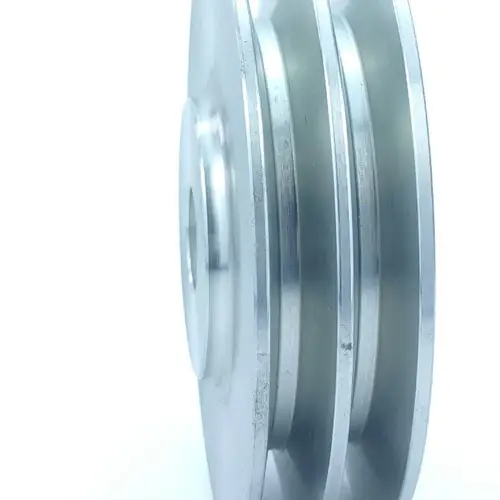

Types and Characteristics of Sheave Pulley

There are various types of sheave pulleys available, each with its own unique characteristics. One common type is the fixed sheave pulley, which provides a stable and consistent rotation. Another type is the adjustable sheave pulley, allowing for flexibility in adjusting the speed and tension of the system. Additionally, there are also multi-groove sheave pulleys that can accommodate multiple belts, increasing the load capacity.

Advantages of Sheave Pulley made of Different Materials

The material used in the construction of a sheave pulley greatly influences its performance and durability. Sheave pulleys made of stainless steel offer excellent corrosion resistance, making them suitable for marine applications. Pulleys made of aluminum are lightweight yet strong, making them ideal for applications that require weight reduction. Furthermore, sheave pulleys made of nylon are known for their low friction coefficient, reducing wear and prolonging the lifespan of the system.

Application of Sheave Pulley in Various Fields

Sheave pulleys find applications in a wide range of industries, showcasing their versatility and importance. In the construction industry, sheave pulleys are used in lifting and hoisting operations, providing the necessary mechanical advantage. In elevators, sheave pulleys play a crucial role in the smooth and efficient movement of the elevator car. Industrial machinery relies on sheave pulleys for power transmission and speed control. Stage equipment, such as theater rigging systems, utilize sheave pulleys for smooth and precise movements. Lastly, in marine applications, sheave pulleys are essential for various operations on ships and boats.

Future Development Trends and Opportunities

The future of sheave pulley products is promising, with several development trends and opportunities on the horizon. As technology advances, the demand for more efficient and compact sheave pulleys is expected to rise. Additionally, the increasing focus on sustainability and energy efficiency presents an opportunity for the development of eco-friendly sheave pulleys. Furthermore, the growing construction and industrial sectors in emerging markets offer potential growth opportunities for the sheave pulley industry.

Choosing a Suitable Sheave Pulley

Selecting the right sheave pulley requires careful consideration of various factors. The load capacity is an important consideration, as it determines the maximum weight the pulley can handle. The material of the pulley should be chosen based on the specific application requirements, considering factors such as corrosion resistance and weight. The diameter and size of the sheave pulley should be compatible with the system it is intended for. Additionally, the type of pulley, whether fixed or adjustable, should be chosen based on the desired functionality. Lastly, the bore size of the pulley should match the shaft it will be mounted on to ensure proper alignment and efficient operation.

In summary, sheave pulleys offer excellent performance characteristics and are available in various types and materials. Their applications in construction, elevators, industrial machinery, stage equipment, and marine applications highlight their importance in multiple industries. The future of sheave pulley products looks promising, with opportunities for innovation and growth. When choosing a sheave pulley, factors such as load capacity, material, diameter and size, type of pulley, and bore size should be carefully considered to ensure optimal performance.